Automation

Reference project

Maximum flexibility in a modular robot cell

Maximum flexibility in a modular robot cell

Robot combines workpiece, fixture and tool handling in a five-stage complete solution

Goal

- Automated loading of a G550 5-axis machining center with workpieces and fixtures

- Plant with one employee in 3-shift operation and unattended production on weekends

Work piece

- 30 different worm screw jacks, cast and aluminum

- Batch size from 1 – 200

- Workpiece weights between < 1 kg to about 80 kg

Challenge

- Large variety of parts, which require high level of manufacturing flexibility

- Limited area in the production hall

- ERP integration required

Machining

- OP10

- OP20

- Automated deburring

- Automated cleaning

Description of plant

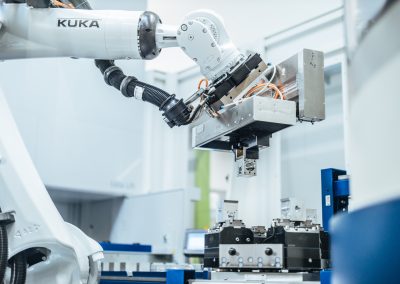

- Modular VB robot cell

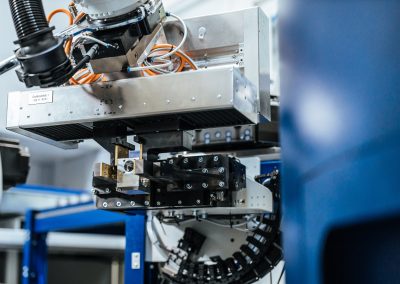

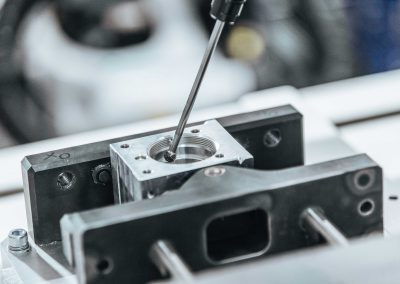

- DockLock zero-point clamping system on machine and feed table, setup area for operator and robot flange

- Hydraulic 4-way clamping fixture with embossing and pendulum jaws

- Lift system with automated storage, height: 4 meters

- Loading and unloading in the rear during automated processing

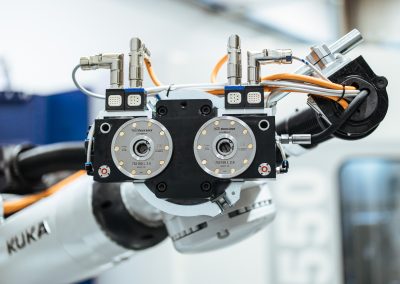

- KR240 robot for fixture, workpiece tray and double gripper

- KR10 robot for deburring

- Master computer software for networking

Savings

- Higher machine utilization due to assured process reliability also in unattended shifts

- Improved quality due to consistent processes

- Analyses of statistics in the production process enable better optimization

Here we go

Let us help you enter the age of automation

As part of the HAINBUCH Group, Vischer & Bolli Automation GmbH is a specialist and general contractor for the automation of entire manufacturing cells.