HAINBUCH GROUP

Vischer & Bolli Automation

As part of the HAINBUCH GROUP Vischer & Bolli Automation GmbH is a specialist for all aspects of workholding technology and automation.

Automation

Robot cells for production systems that require milling, turning, grinding, assembly and other processes

Automated workholding technology

Automated clamping devices (hydraulic and pneumatic) with sensor technology

Manual workholding technology

For all manufacturing plants with requirements for high-end clamping devices

High-performance cutting

HPC tools for milling, drilling and thread cutting

Toolholder systems

powRgrip high-performance tool holders for HPC machining

Mission & Vision

Automation and workholding technology from a single source

We, Vischer & Bolli Automation GmbH with headquarters in Lindau on Lake Constance, have long specialized in creative clamping solutions for the advanced automation of entire manufacturing cells. Recently we became part of the family operated HAINBUCH Group, which allows us to make full use of interesting technological synergy potentials. Together we continue to expand and develop in the area of automation and digitization.

Automation

We offer automated complete solutions: engineering of the robot cell, entire workholding technology, grippers, storage solutions, sensors, software and peripherals.

Solutions

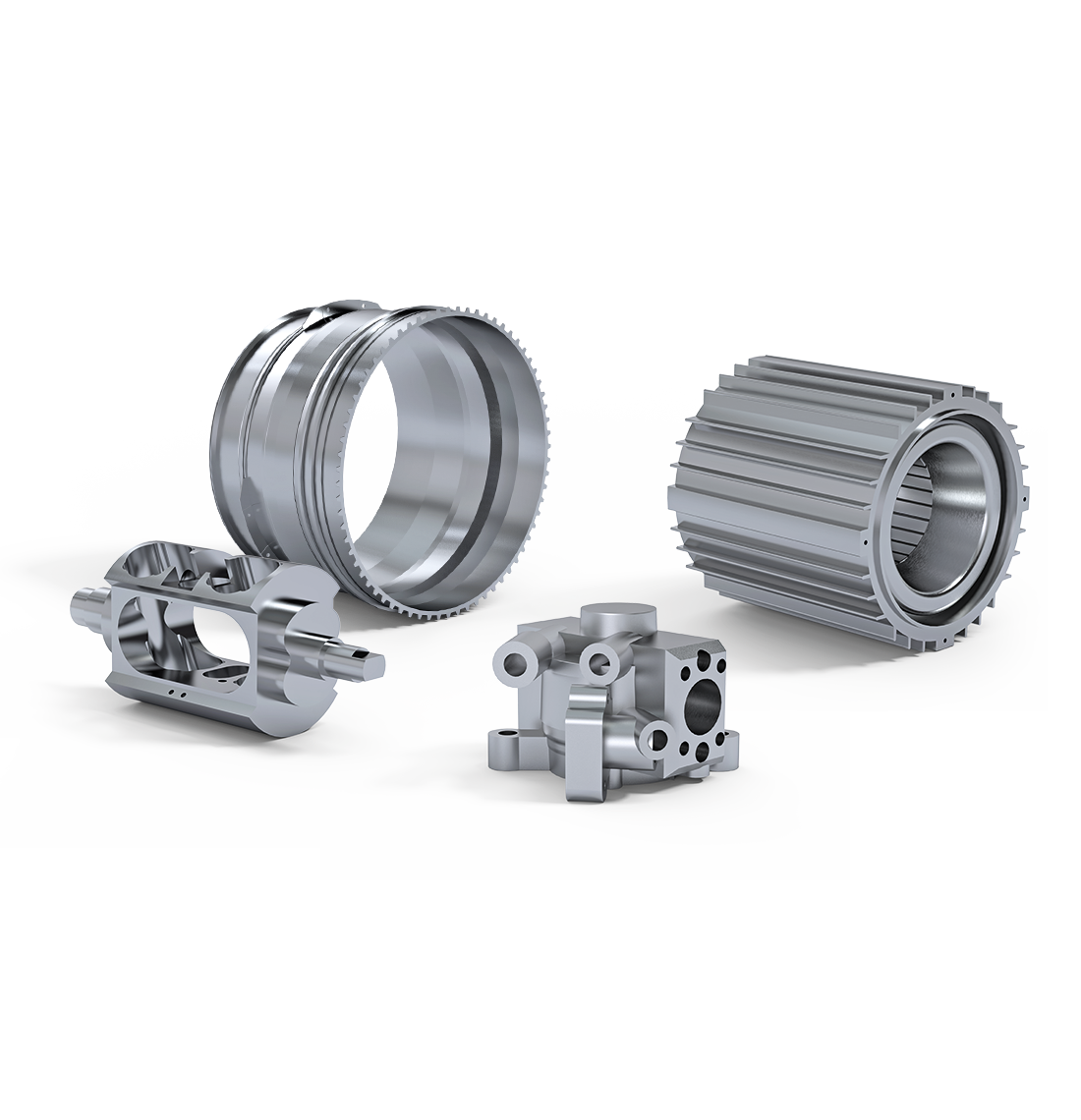

The workpiece is at the center of attention – we define an optimal clamping solution and a suitable automation concept.

E-Shop

Browse through our product portfolio and use our e-shop for fast and convenient ordering.

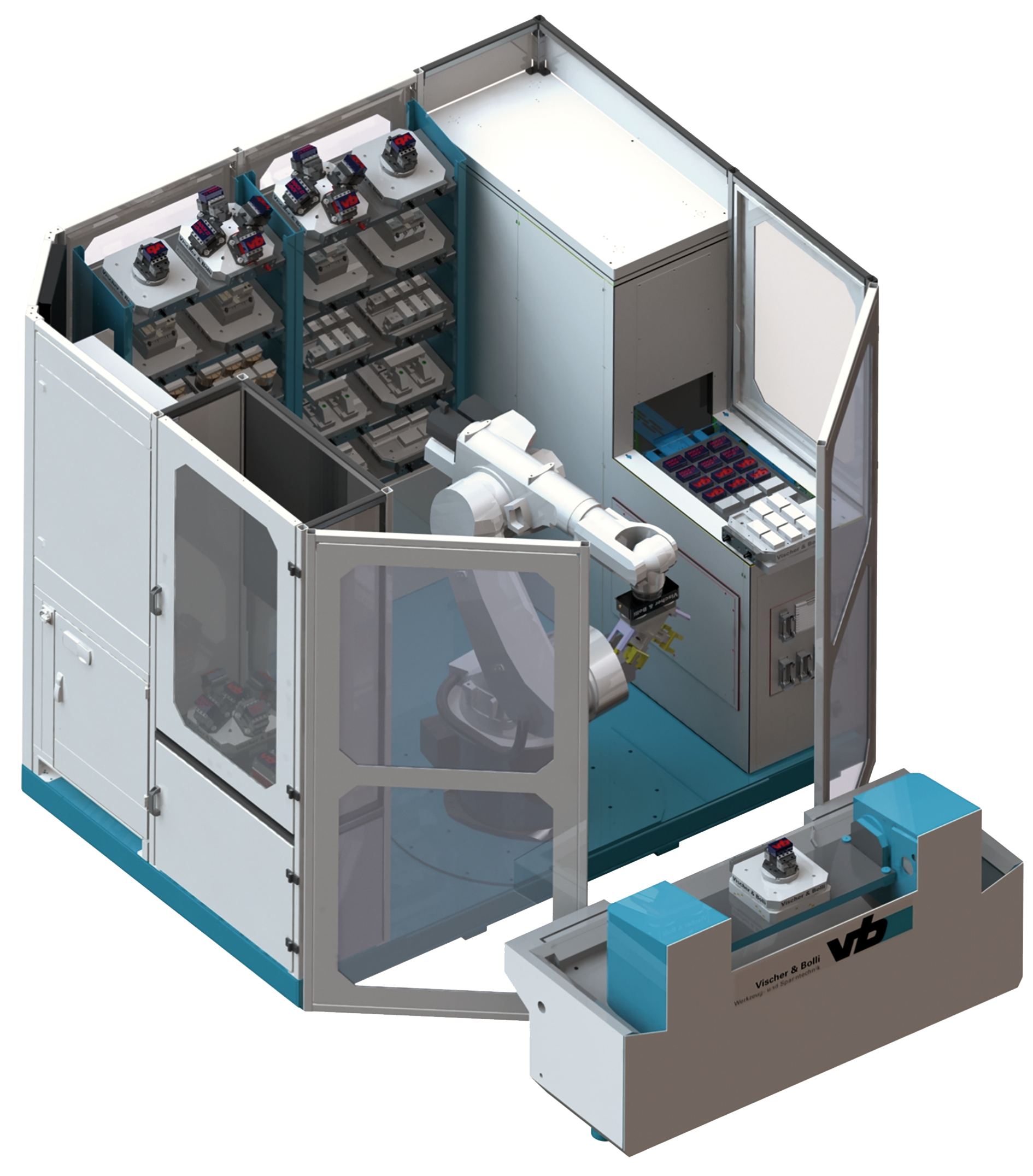

Reference project

Maximum flexibility in a modular robot cell

Robot cells for workpiece, fixture and tool handling for small, mid-sized and large plants.

Services

What can we do for you?

All-In-One Bundles

Vischer & Bolli Automation GmbH offers comprehensive workholding technology and automation projects – all from a single source.

Utmost quality

We attach great importance to quality and smooth processes, as well as maximum functionality and productivity.

Best customer service

Our widespread partner and service network allows us to offer you extensive advice and support.

Sustainability

One of the most important goals of Vischer & Bolli Automation is the sustainable implementation of projects for the customer and the environment.

Fair price-performance ratio

Our state-of-the-art production solutions increase efficiency at very interesting prices.

Experience

Vischer & Bolli Automation GmbH can boast more than 30 years of experience in international projects.

Automation solutions

Vischer & Bolli automation robot cells

The absolute added value of these automation solutions is the modular design in different stages. They are based on modular pallet-loading systems for direct workpiece loading with automated changing of the fixture. The number of fixtures, workpieces and toolholders is variable.

Due to custom requirements, upgrade stages and clamping technology have undergone continuous development in recent years. The robot cell is designed for one-off and serial production, and can be used in combination with any machine tool, for milling, turning, grinding and other machining processes.

vb DockLock automation

- Complete solutions for automation with weights from 1 – 500 kg and pallet sizes up to 800 x 800 mm

- Variable number of fixtures, workpieces and toolholders

- Designed for one-off and serial production

- Can be used with any machine tool

- Up to 48 hours of autonomous production with the vb robot cell

- Cost reductions of up the € 200,000.00 per year when used to full capacity

Here we go

Let us help you enter the age of automation

As part of the HAINBUCH Group, Vischer & Bolli Automation GmbH is a specialist and general contractor for the automation of entire manufacturing cells.