Automated workholding technology

Automation of zero-point workpiece clamping

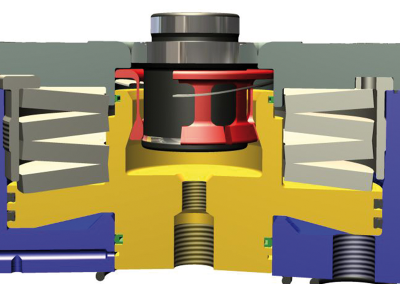

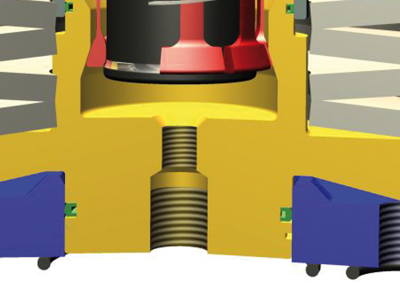

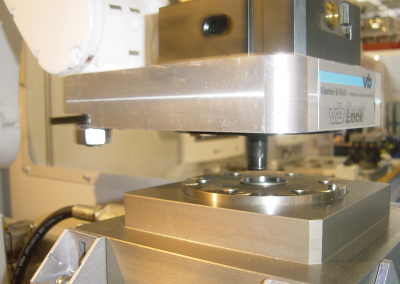

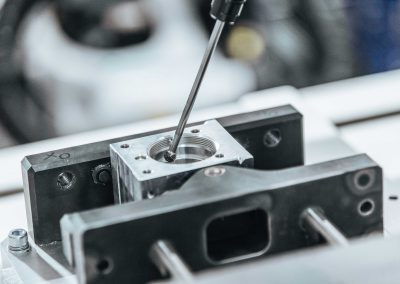

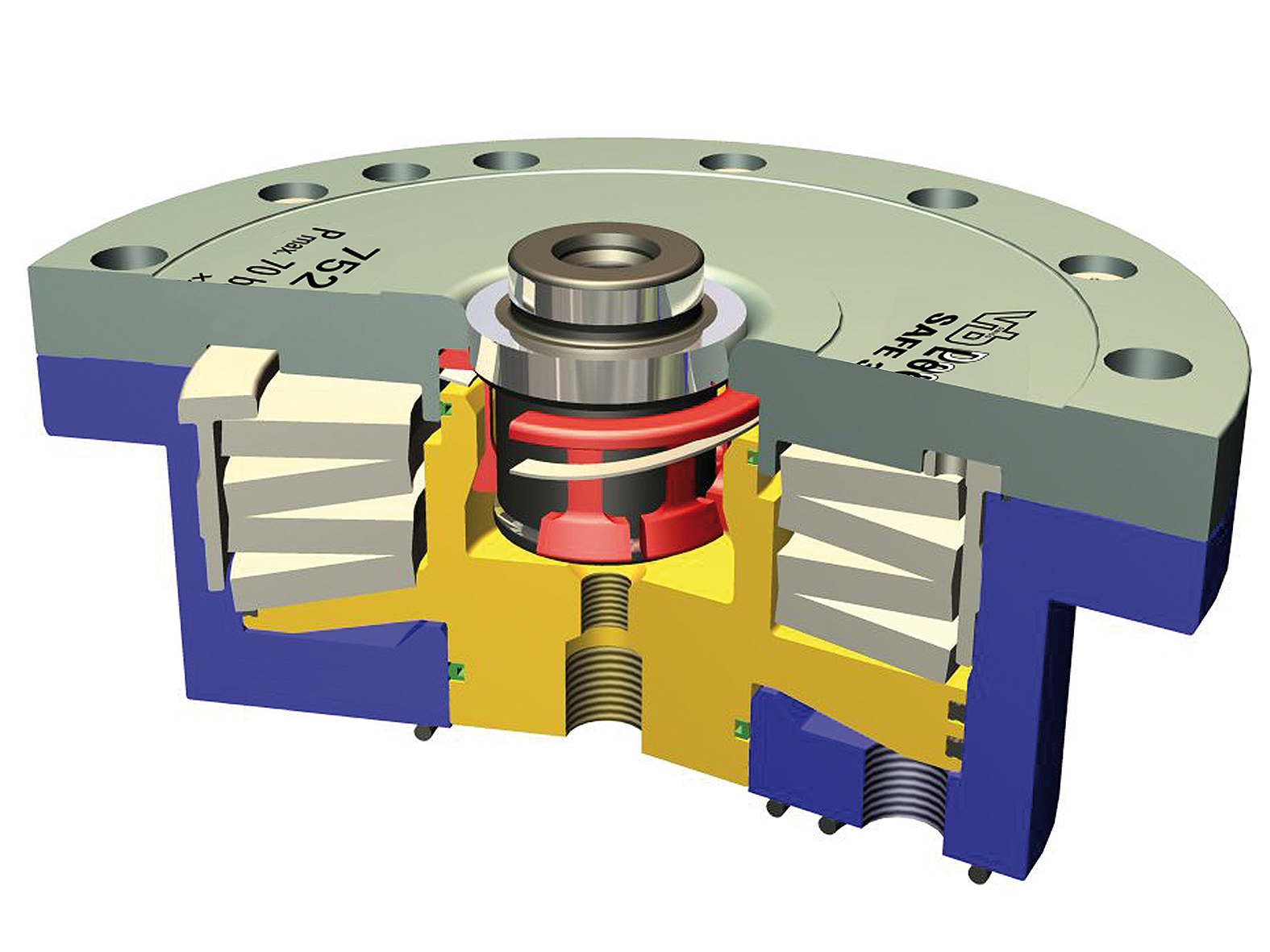

DockLock safe 20 LA

Advantages:

- Repeatability < 5 µm

- Draw-in force: > 12,500 N

- Holding power: > 40,000 N

- Change cycles: > 2,000,000

- Form fit clamping with collet for maximum draw-in forces

- Low wear

- Only 3 moving parts

- With diagonal pull handling and push-up function

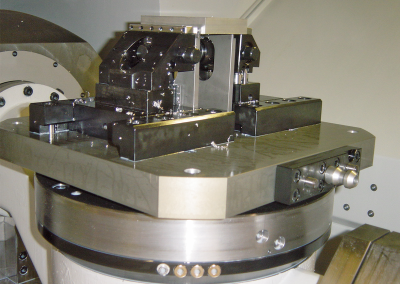

Automation of zero-point workpiece clamping-1

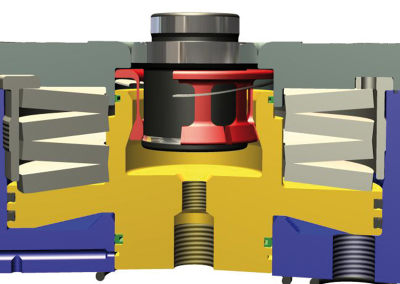

Maximum draw-in and holding force thanks to hydraulically actuated disc springs: mechanical clamping – hydraulic release

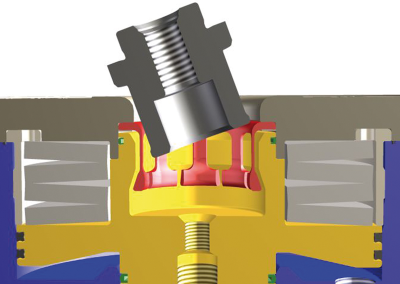

Automation of zero-point workpiece clamping-3

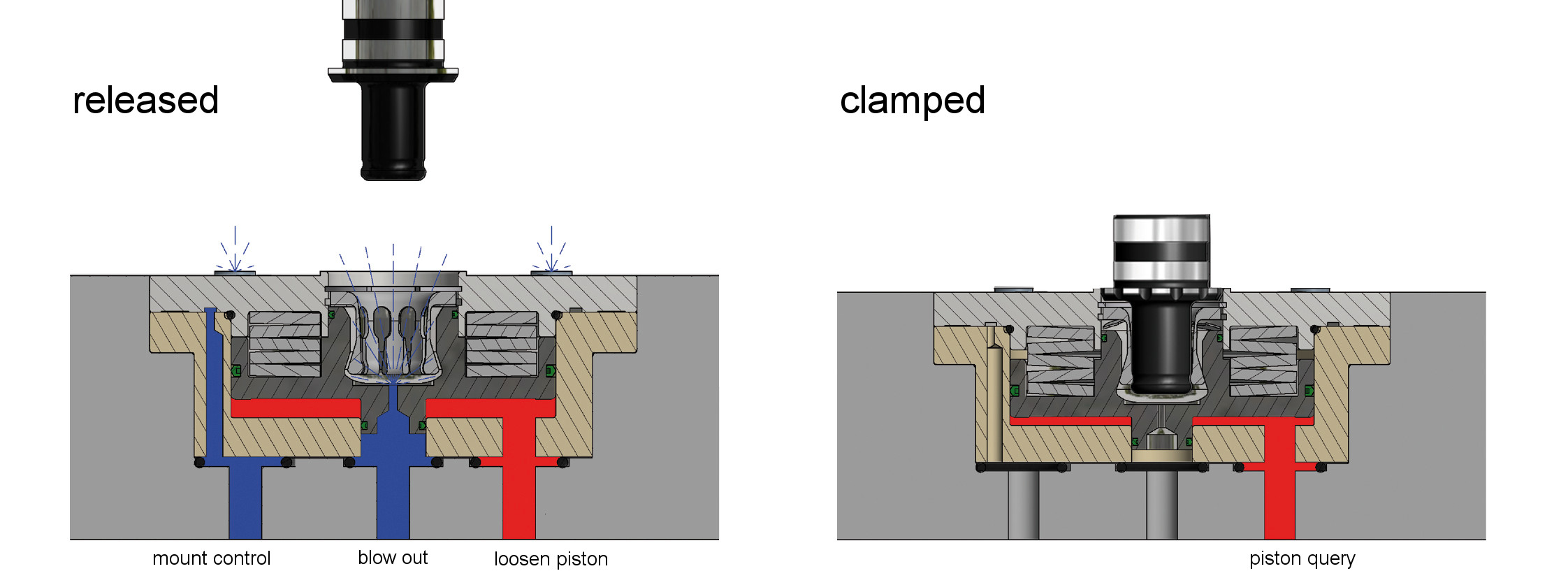

Patented air-blast cleaning and piston monitoring for maximum process reliability

The LA and LAU series, with the advantages listed below, represent a breakthrough in the automation of zero-point workpiece clamping:

- Blow-off of chips and coolant through the middle and via island nozzles

- Total functional reliability due to pneumatic contact control and hydraulic piston position control

- Hold-up effect of the collet, which is important in case of vertical configuration

- Patented collet ensures a form fit and frictional connection and therefore maximum contact of the draw-in bolt

- Pre-centering of clamping bolts facilitates automated loading

- Maintenance friendly due to access from above

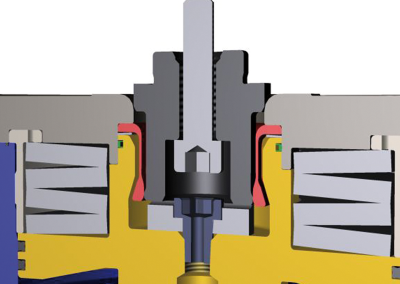

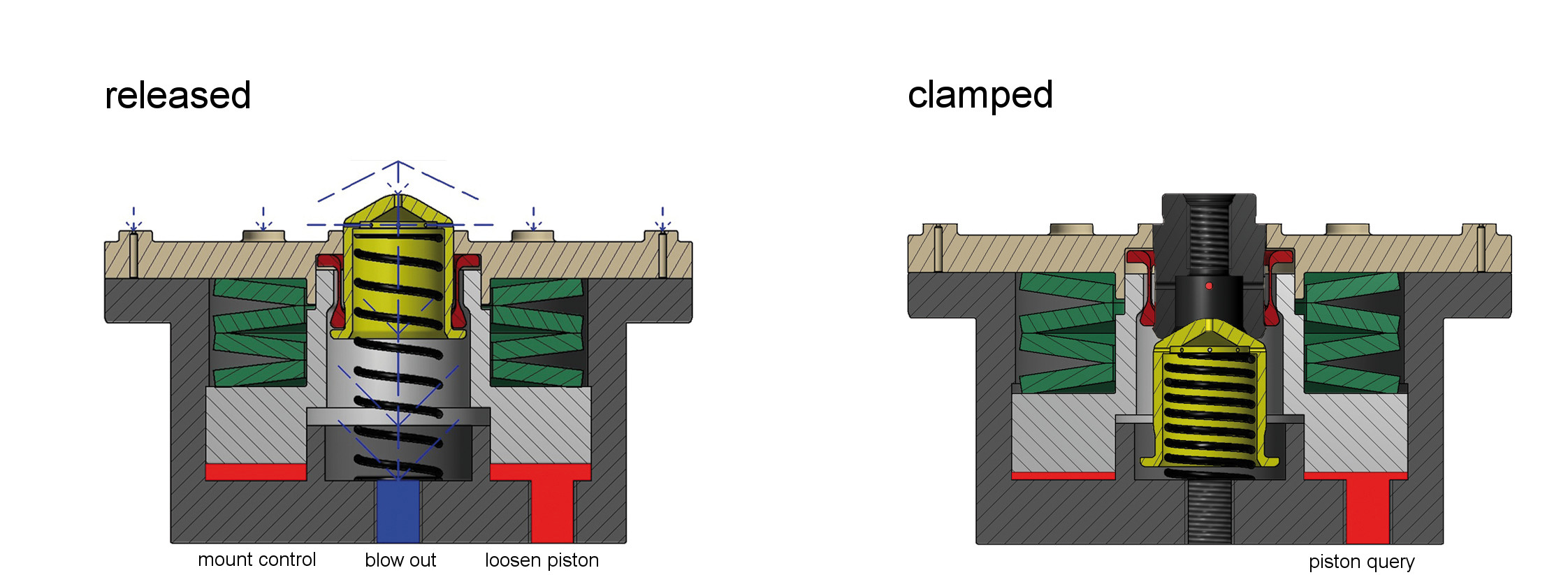

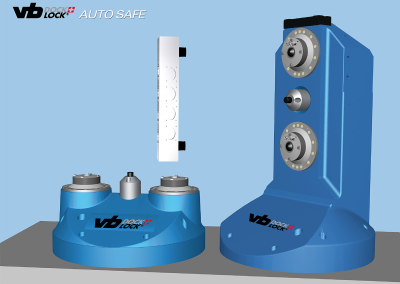

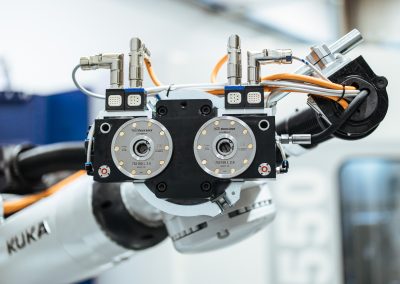

DockLock autosafe 30

The autosafe series, with the advantages listed below, represent a breakthrough in the automation of zero-point workpiece clamping:

- Automated closing of the clamping position ensures complete protection against contamination

- Blow-off of chips and coolant through the middle and via island nozzles

- Total functional reliability due to pneumatic contact control and hydraulic piston position control

- Hold-up effect of the collet, which is important in case of vertical configuration

- Patented collet ensures a form fit and frictional connection and therefore maximum contact of the draw-in bolt

- Pre-centering of clamping bolts facilitates automated loading

- Maintenance friendly due to access from above

- Ventilation at top on cover

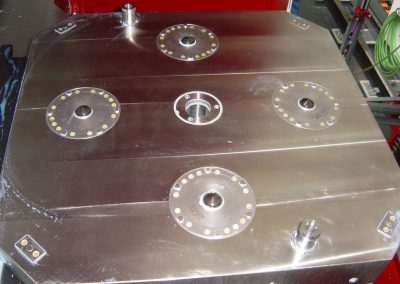

DockLock autosafe 30

Here we go

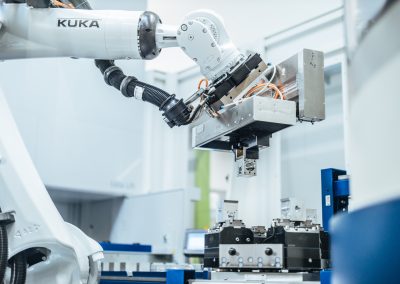

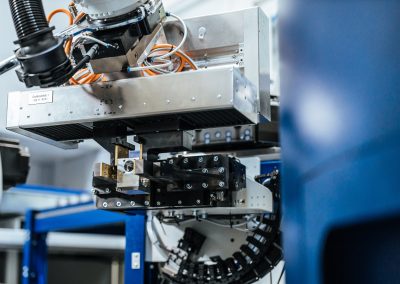

Let us help you enter the age of automation

As part of the HAINBUCH Group, Vischer & Bolli Automation GmbH is a specialist and general contractor for the automation of entire manufacturing cells.