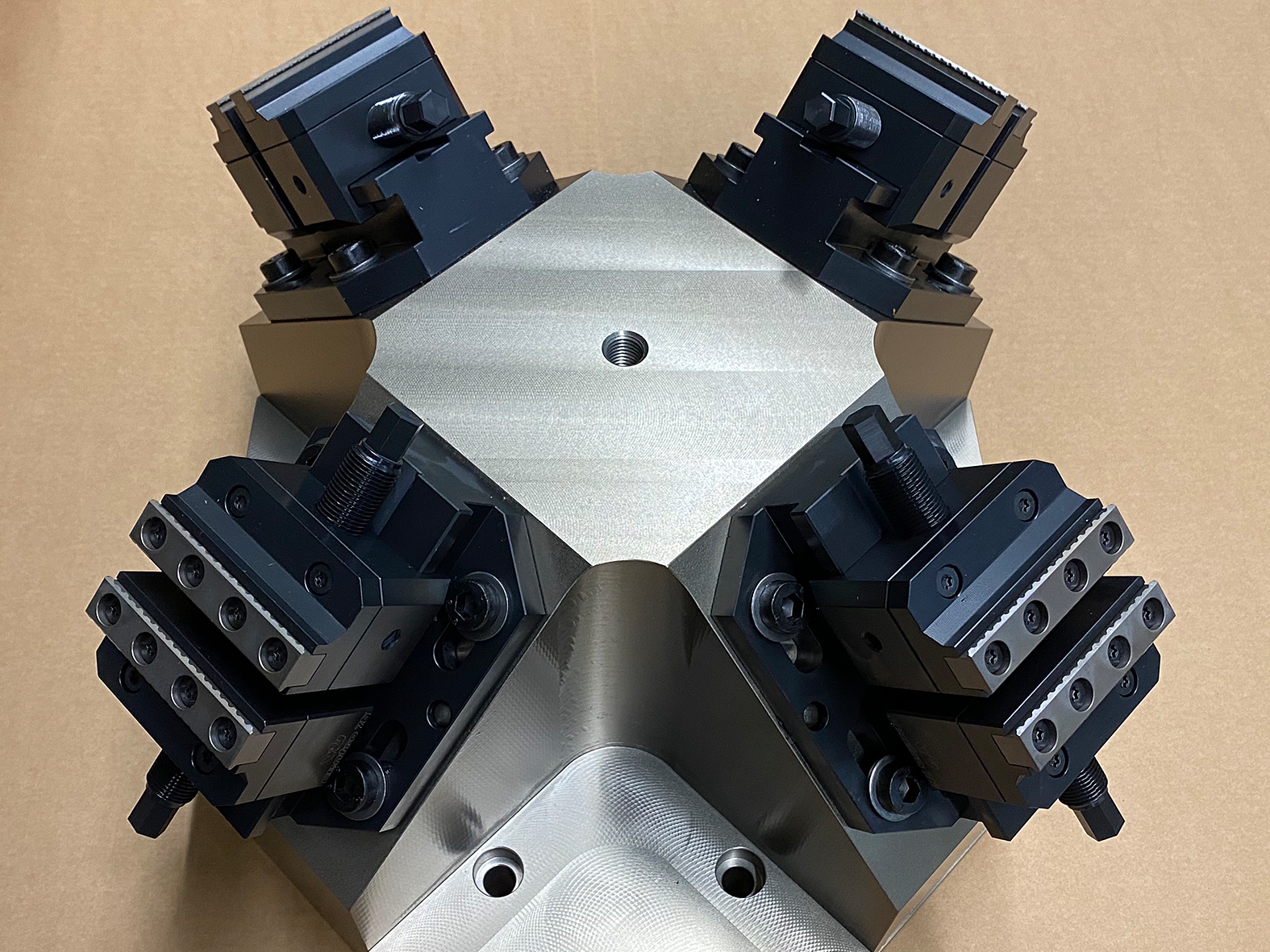

Manual workholding technology

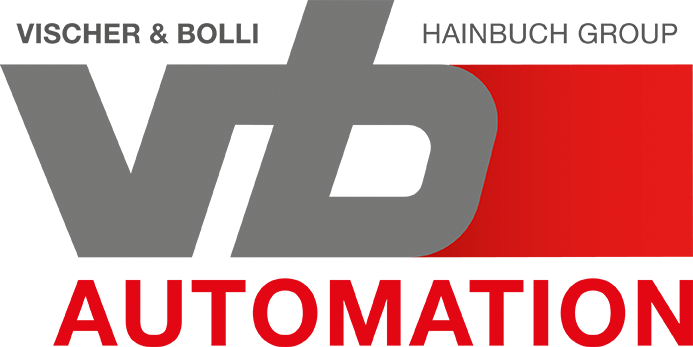

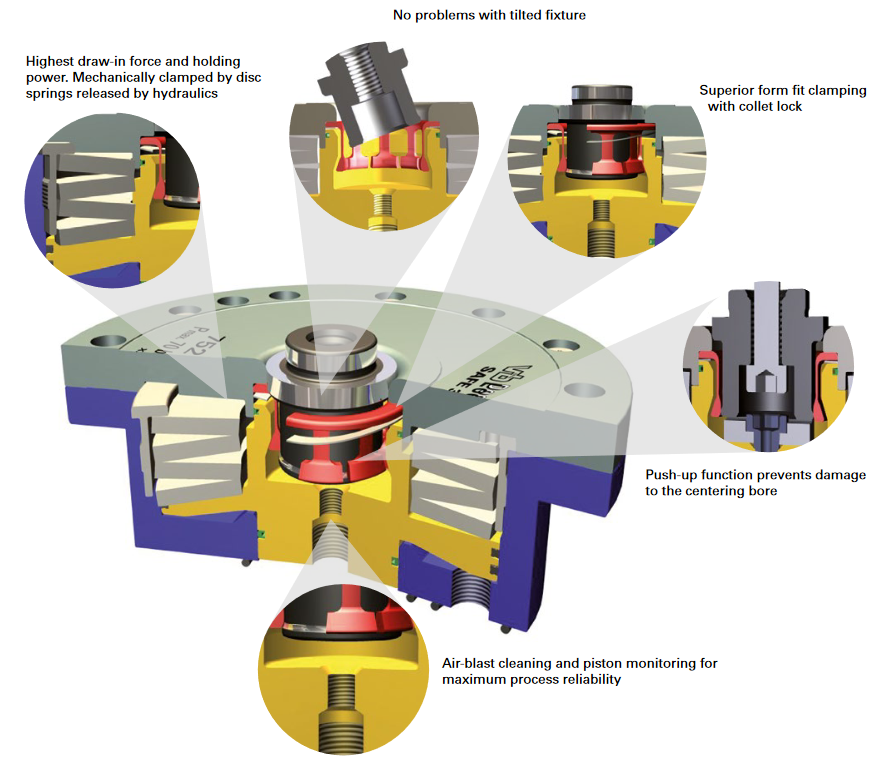

DockLock safe

Hydraulic zero-point clamping system

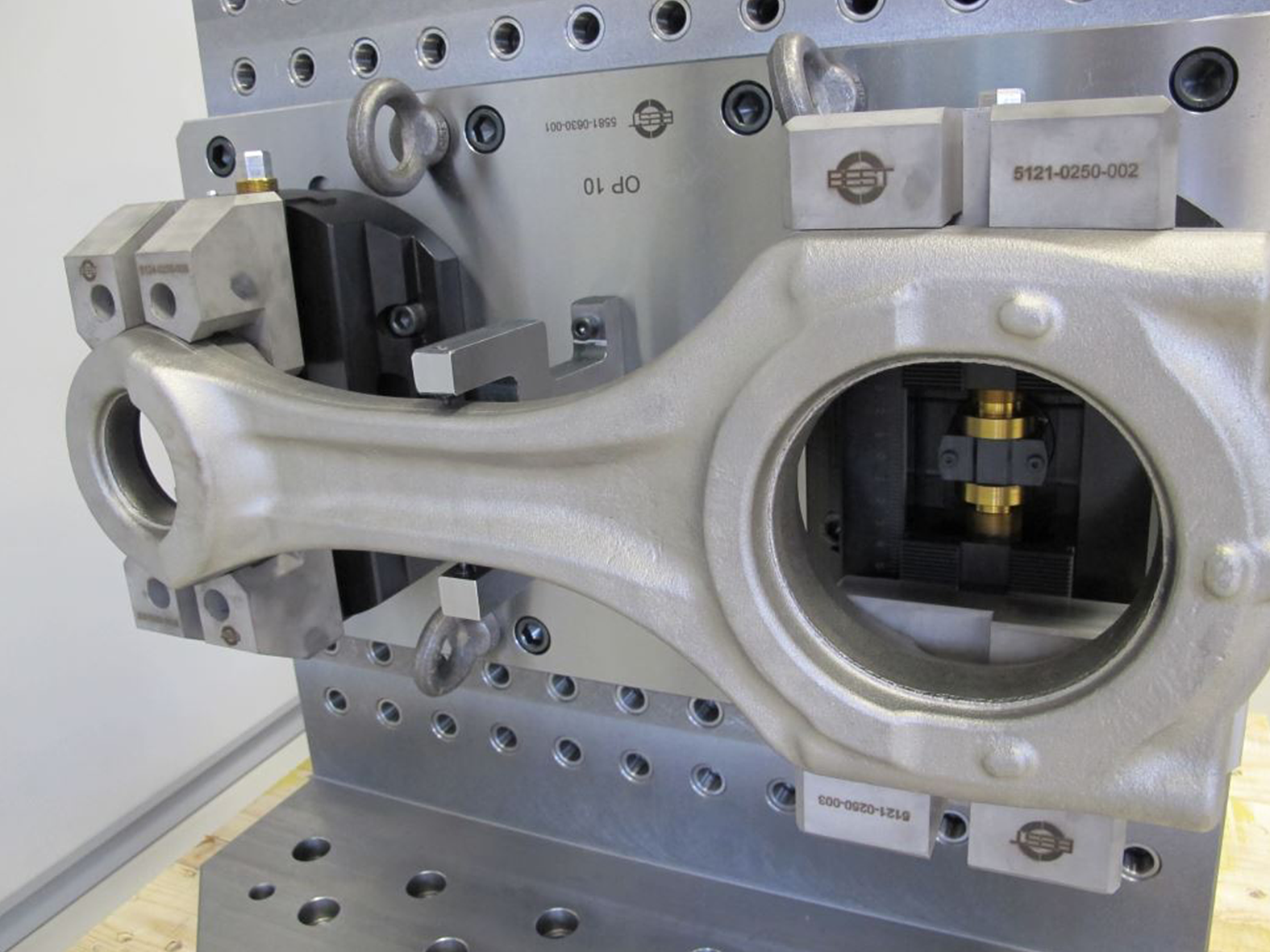

Form fit clamping with collet for maximum draw-in forces, designed for low wear with only three moving parts. With diagonal pull handling and push-up function.

safe20

Draw-in force: > 12.500N | Holding power: > 40.000N | Repeatability < 5 µm

safe30

Draw-in force: > 20.000N | Holding power: > 60.000N | Repeatability < 5 µm

safe50

Draw-in force: > 30.000N | Holding power: > 90.000N | Repeatability < 5 µm

Workpiece change-over in seconds!

Developed by us for you – time-proven design consisting of Rustproof tool steel.

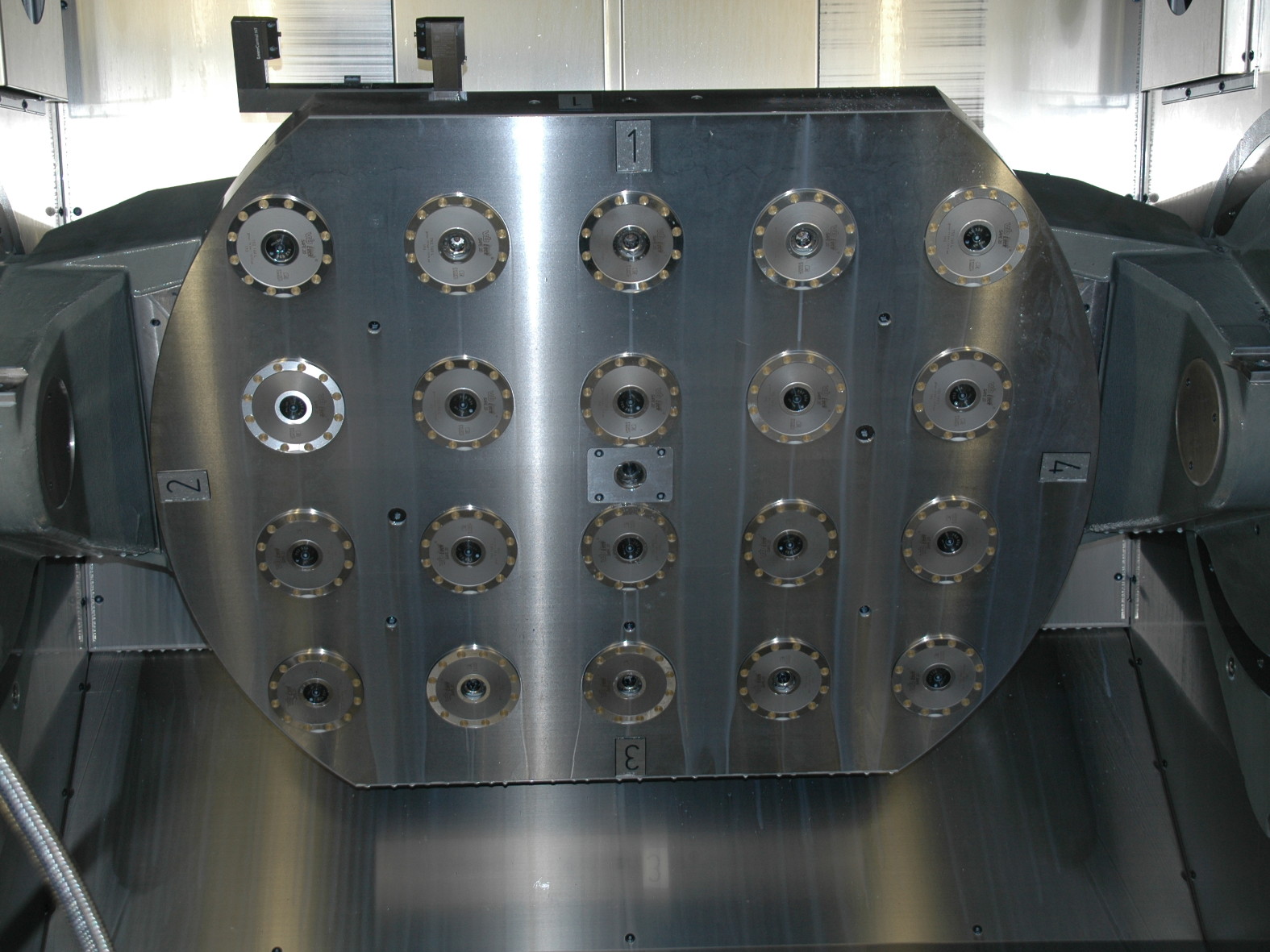

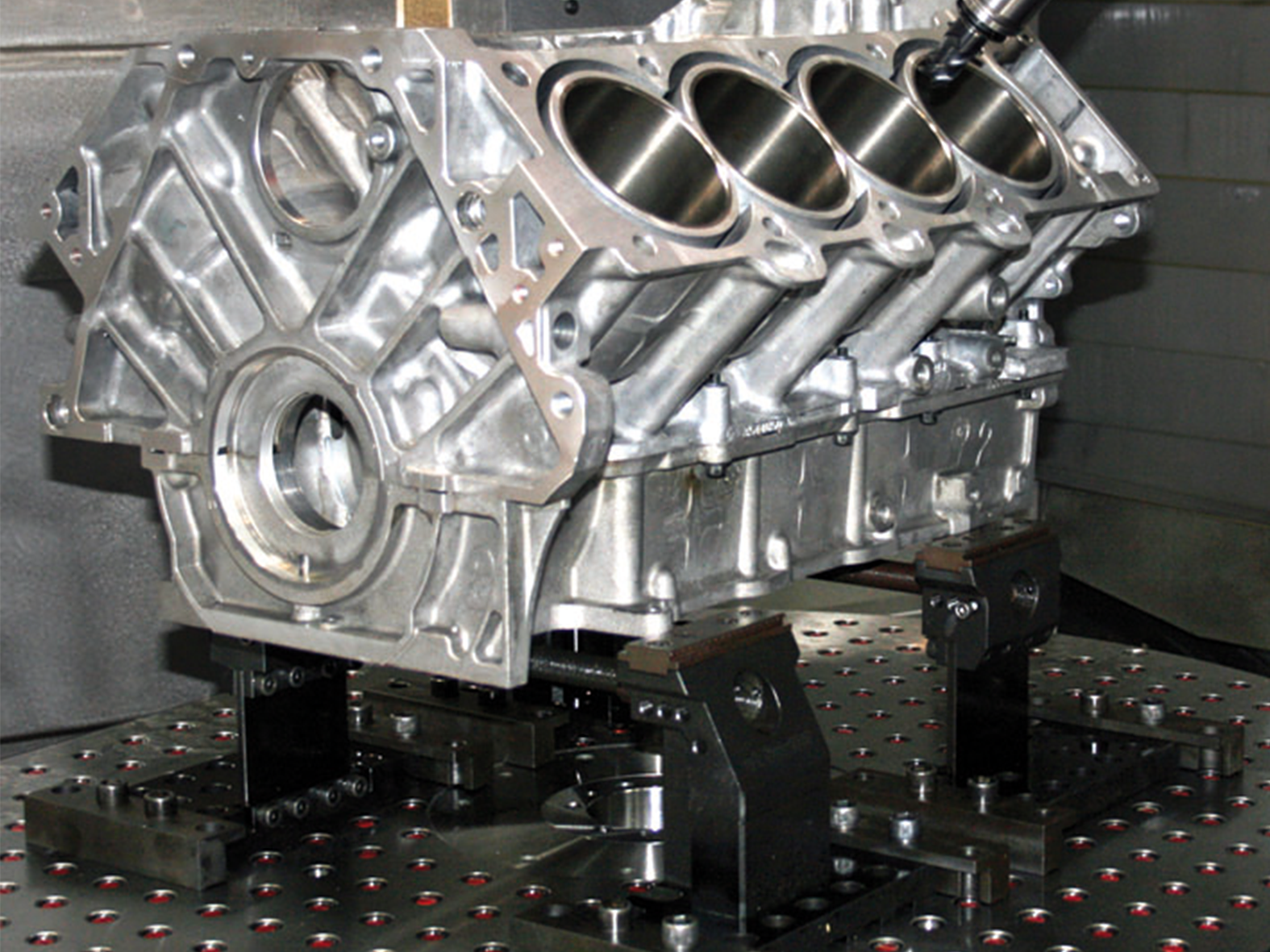

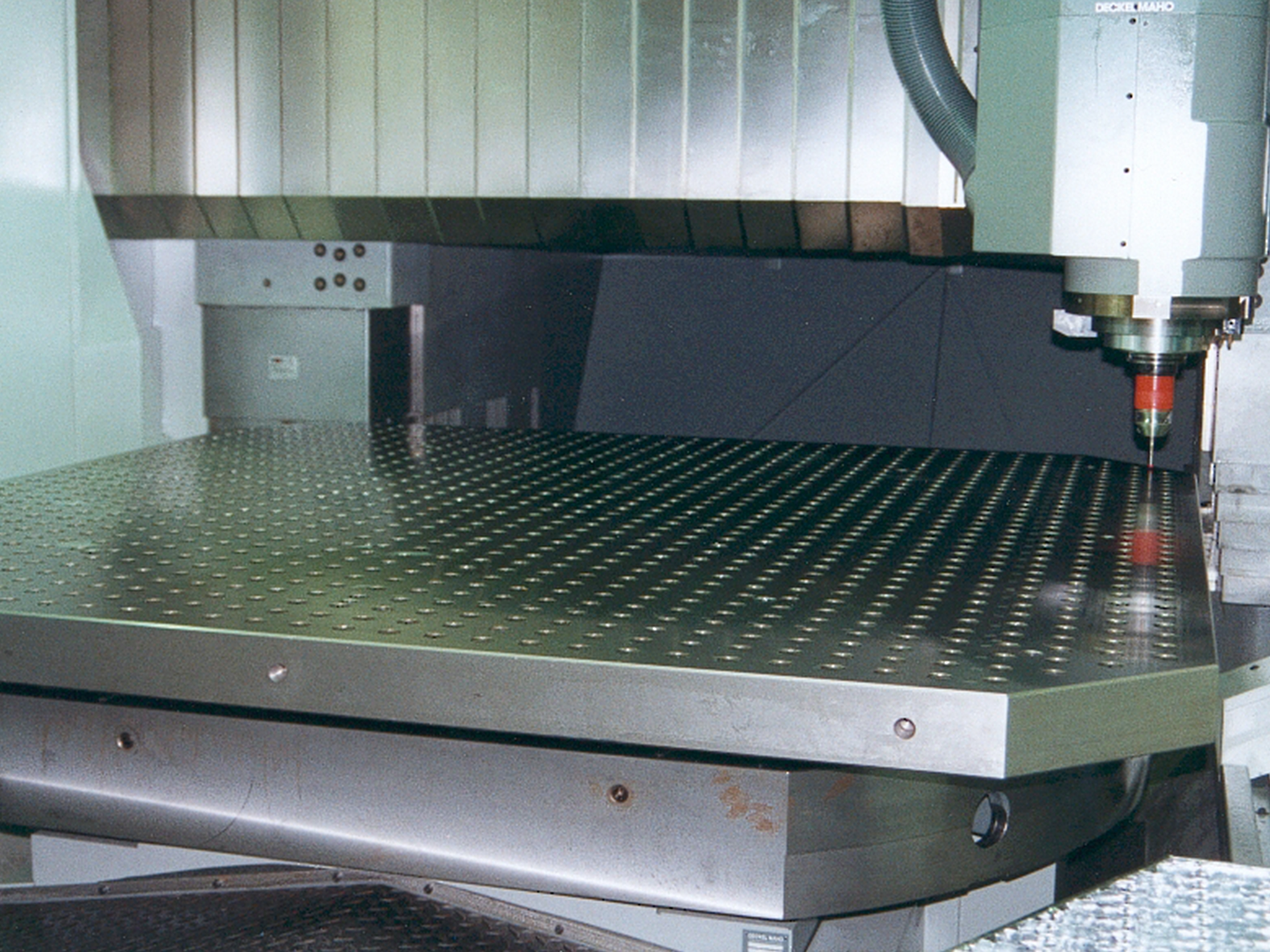

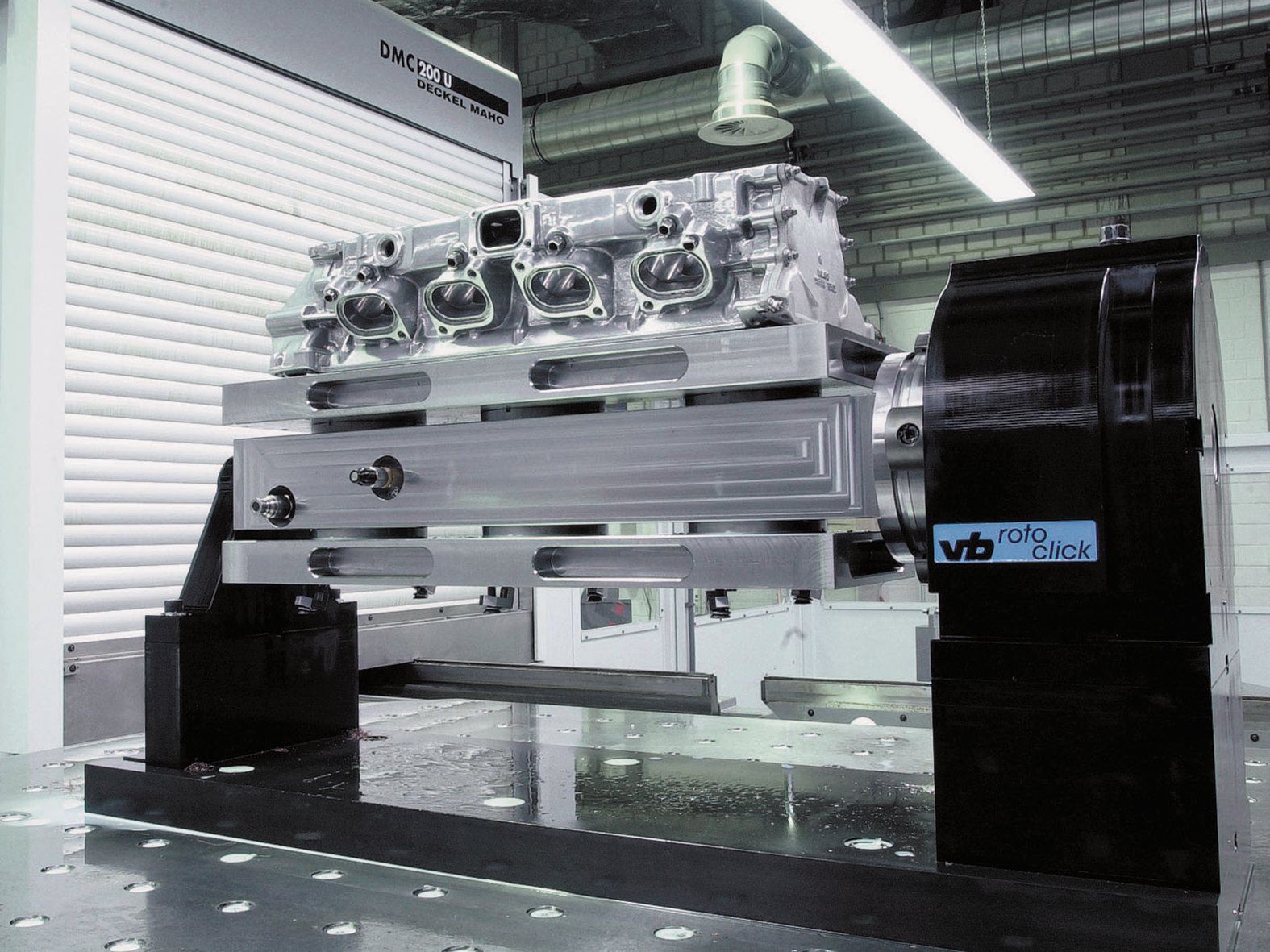

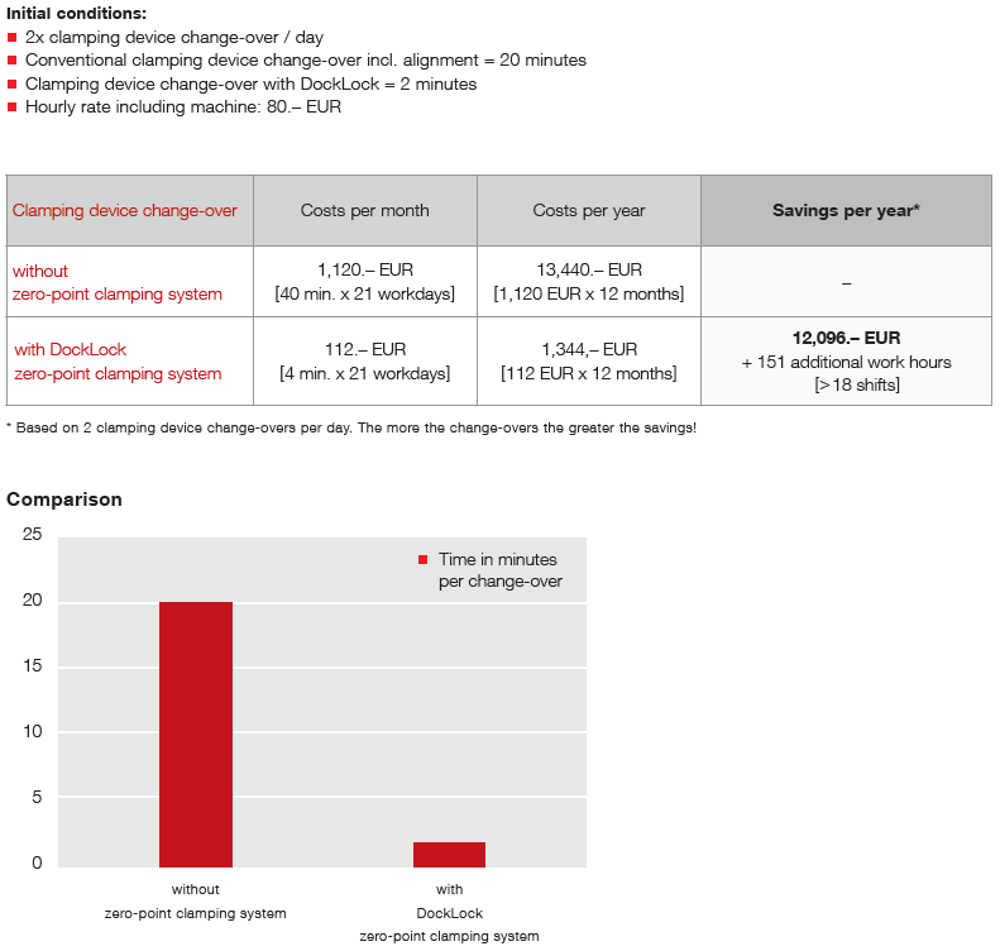

The modular design of the DockLock enormously reduces time and costs in production, while ensuring maximum flexibility of your processes. The universal interface guarantees that setup will take place with no blocking of capacities – namely outside the machine. Whether for measuring, turning, milling, EDM or grinding: DockLock reduces costs, while increasing the speed and flexibility of your production processes. Our extensive experience in zero-point clamping technology enables us to offer you high-quality customized solutions at reasonable cost.

Advantages

- Setup parallel to production time reduces machine downtimes by up to 90 %

- Maximum flexibility allows interruptions for express jobs at any time

- Zero-point repeatability < 5 µm – change-over without repeated measuring

- Inexpensive clamping bolts for convenient retrofitting of existing clamping devices

- Dynamic, vibration-damping, form fit and frictional clamping – improved surface quality, longer tool life and greater reliability

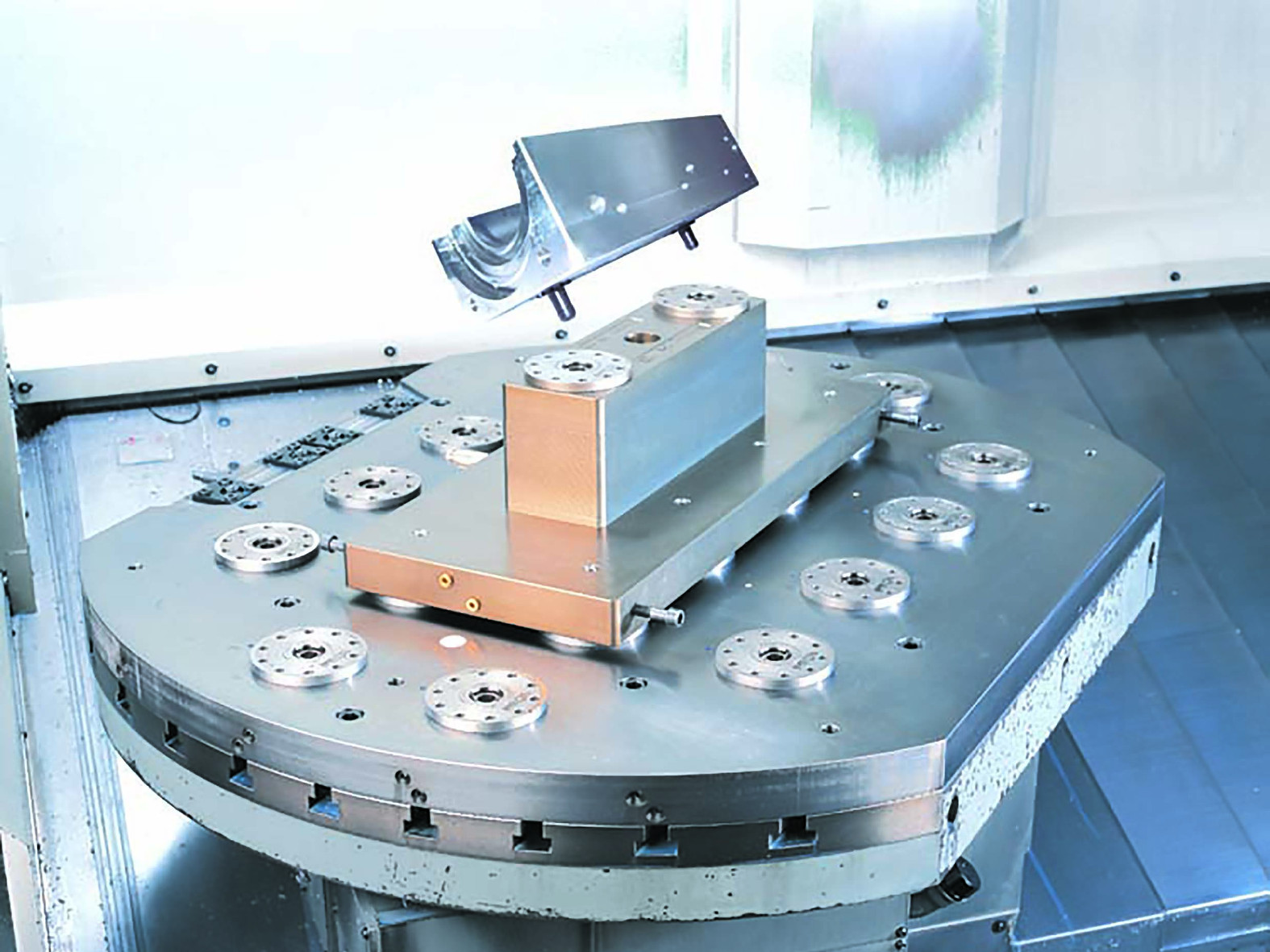

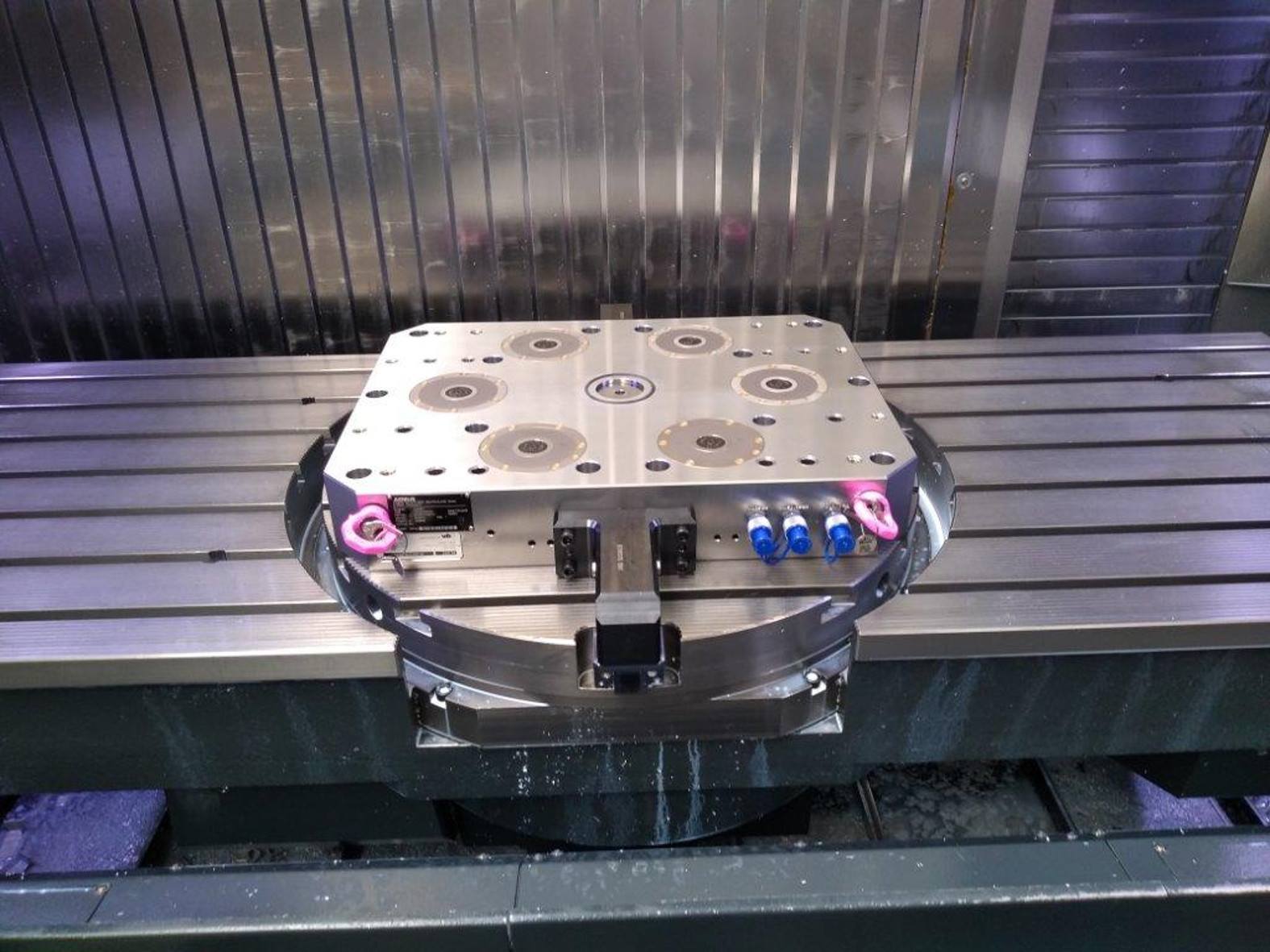

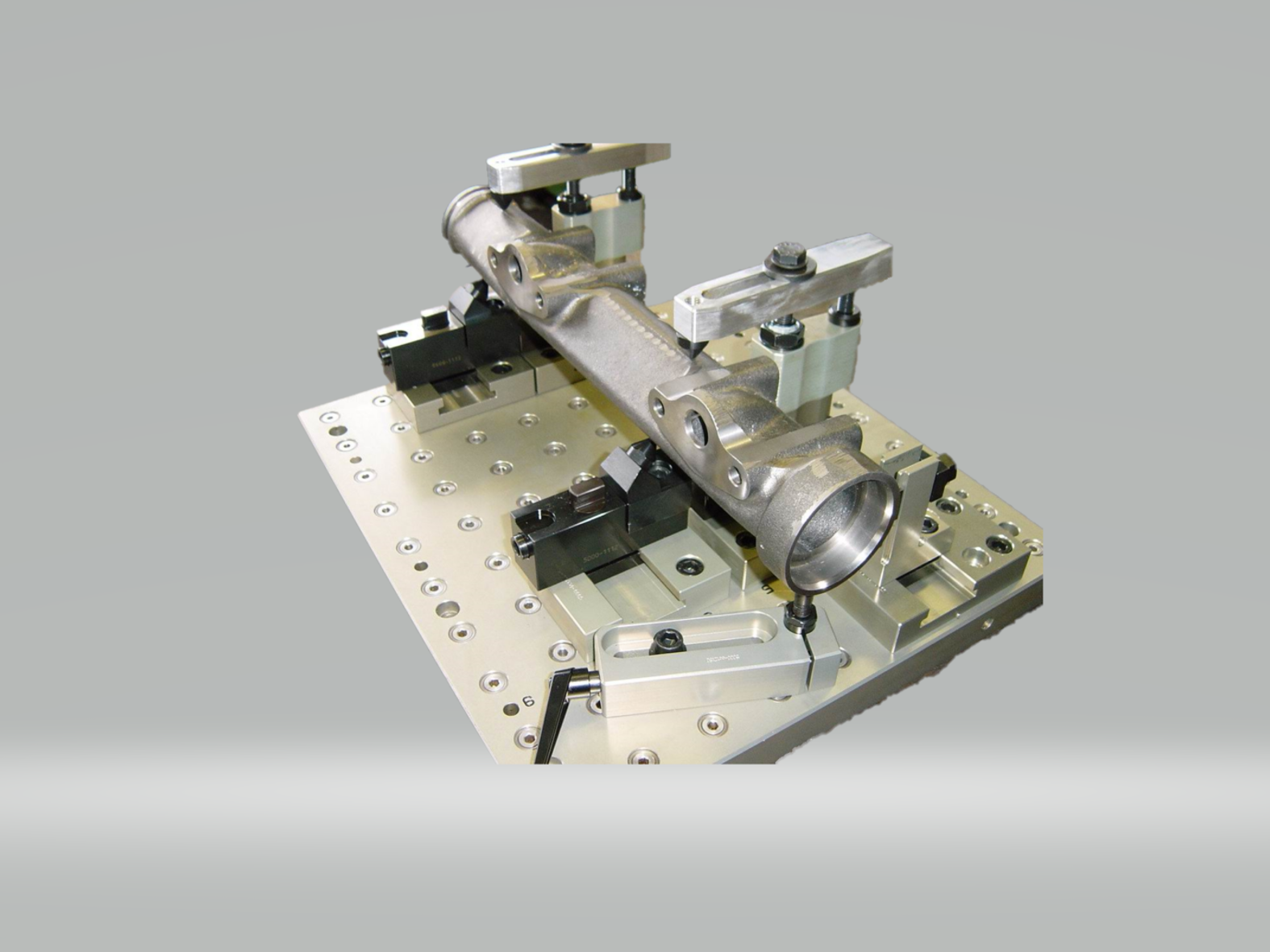

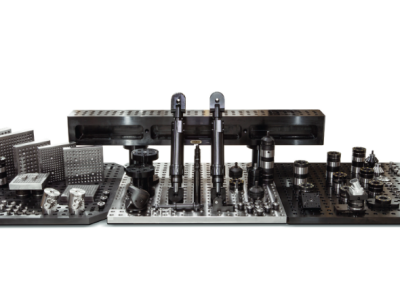

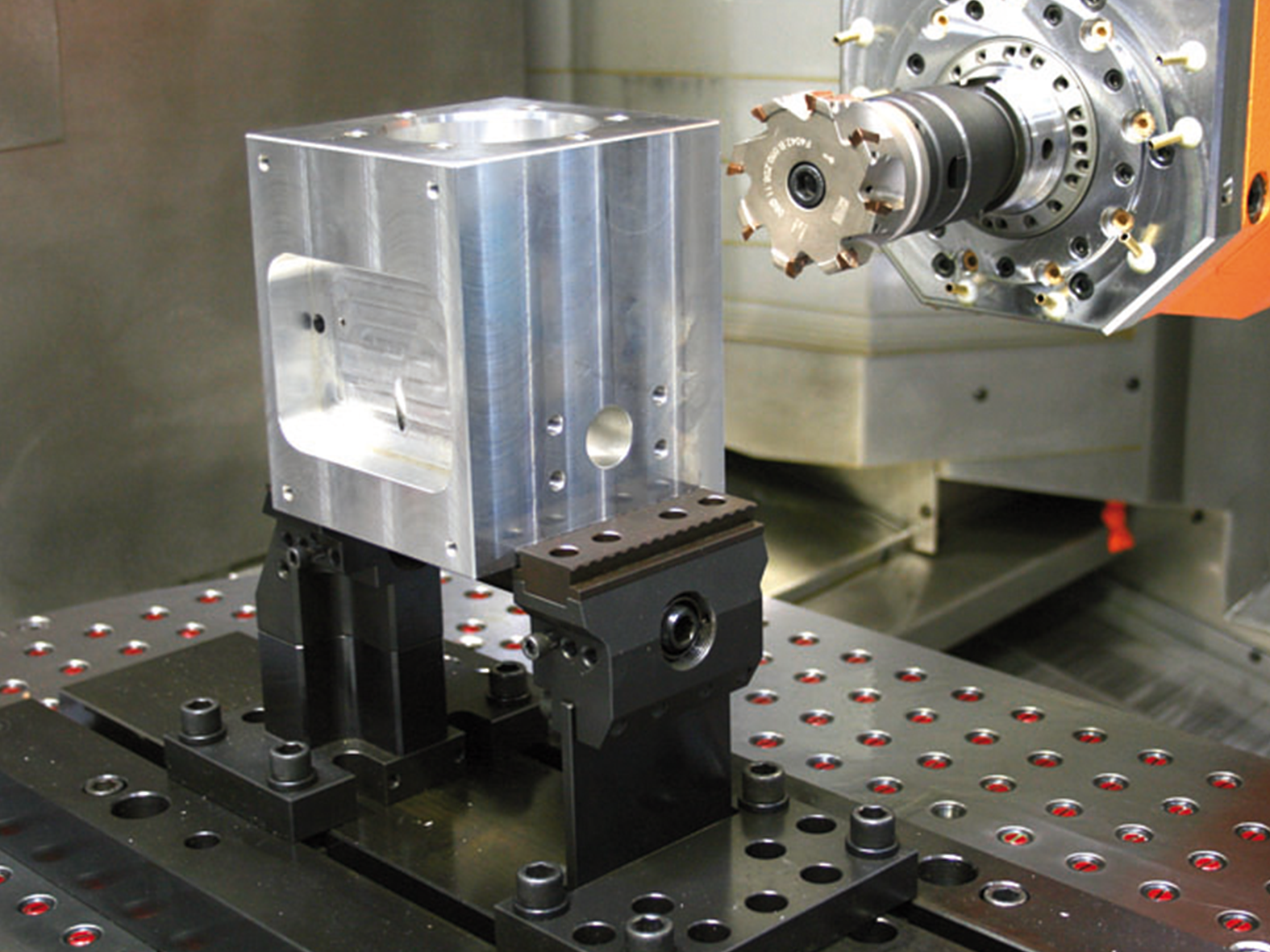

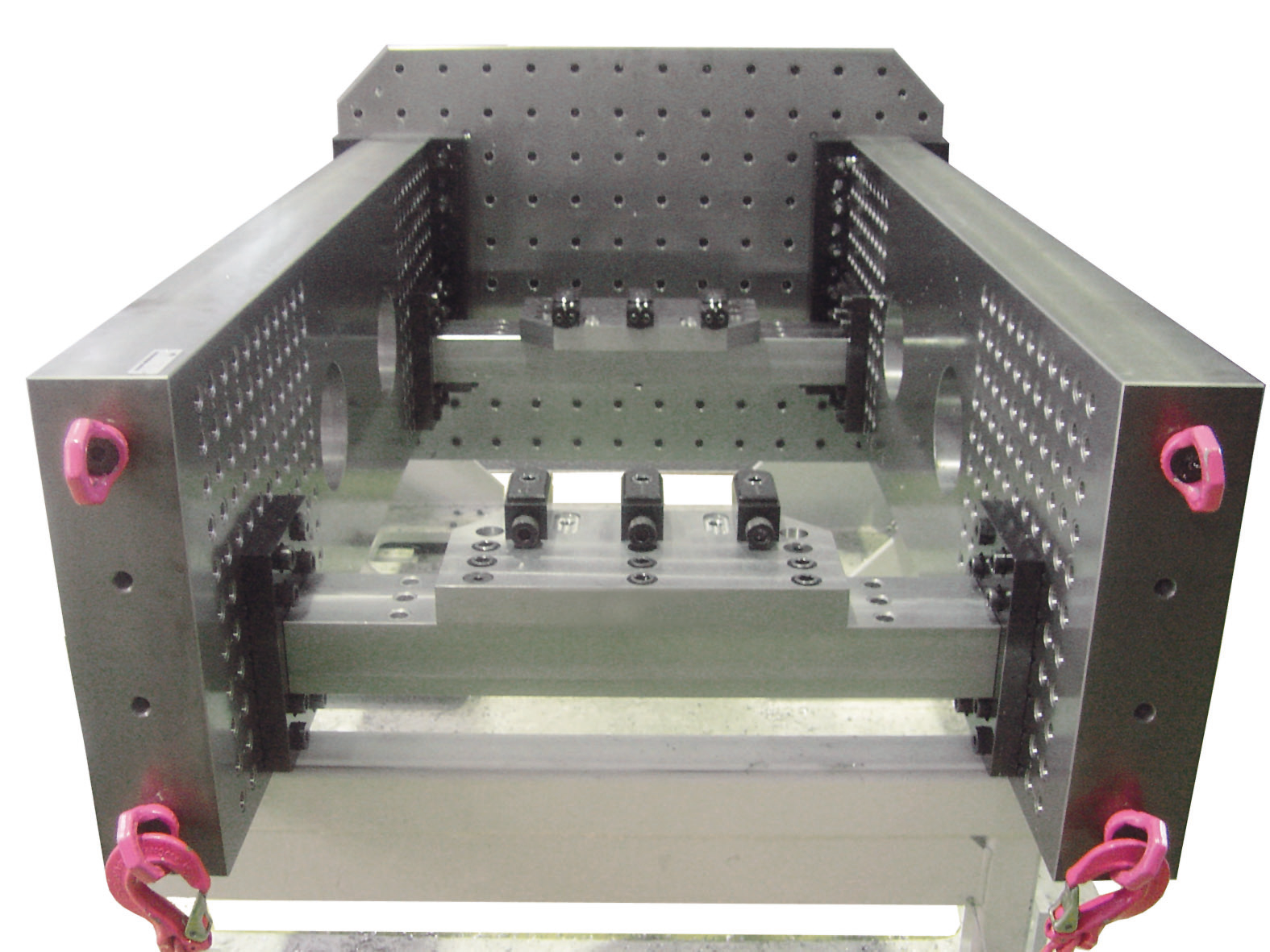

Standardized base plates and built-up cylinders ensure maximum flexibility and are suitable for a broad range of requirements and manufacturing areas

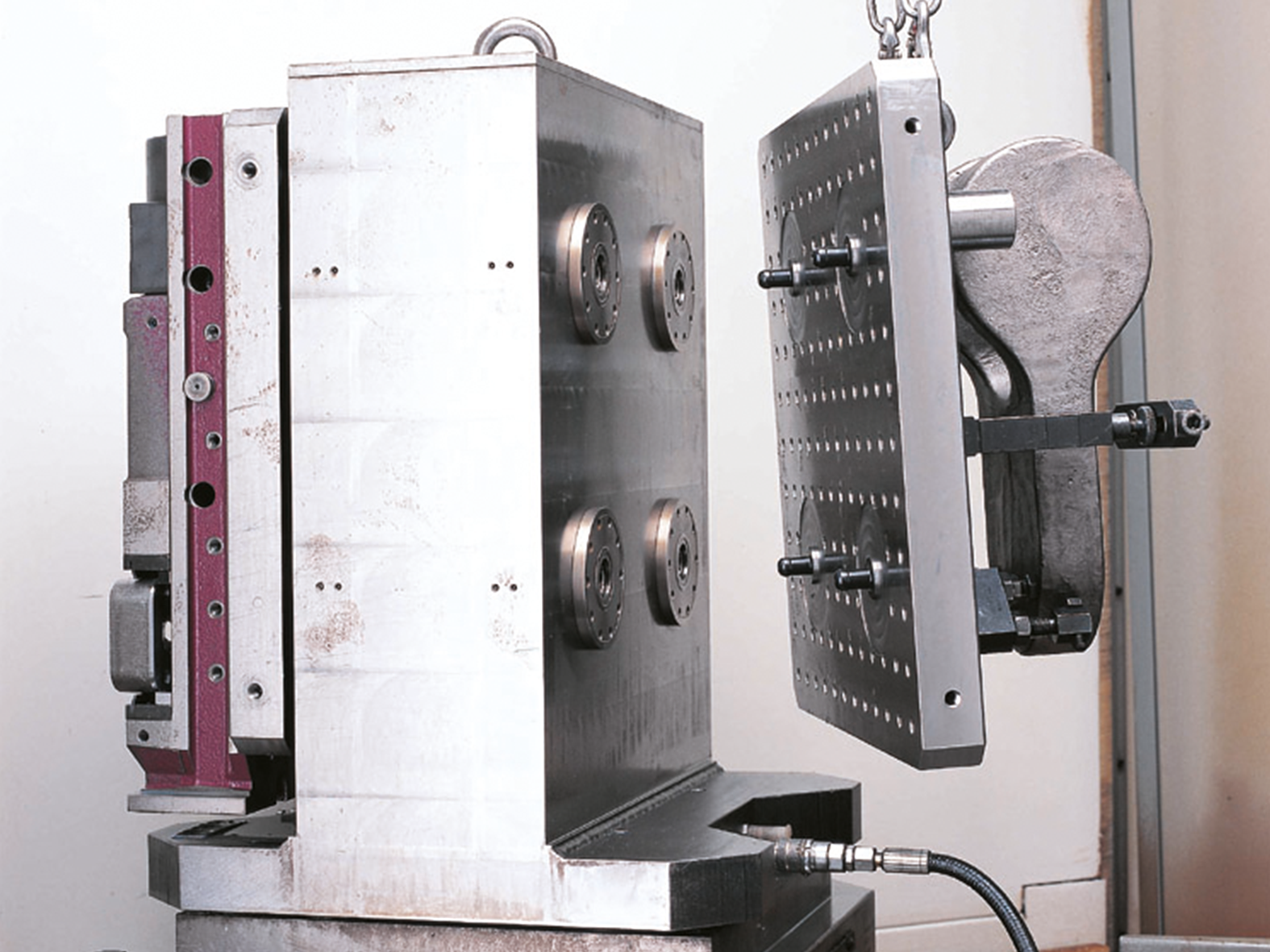

The patented collet lock allows change-over of workpiece pallets with no jamming. A draw-in force of up to 30 kN guarantees a form fit and frictional connection between the zero-point clamping system and the workpiece.

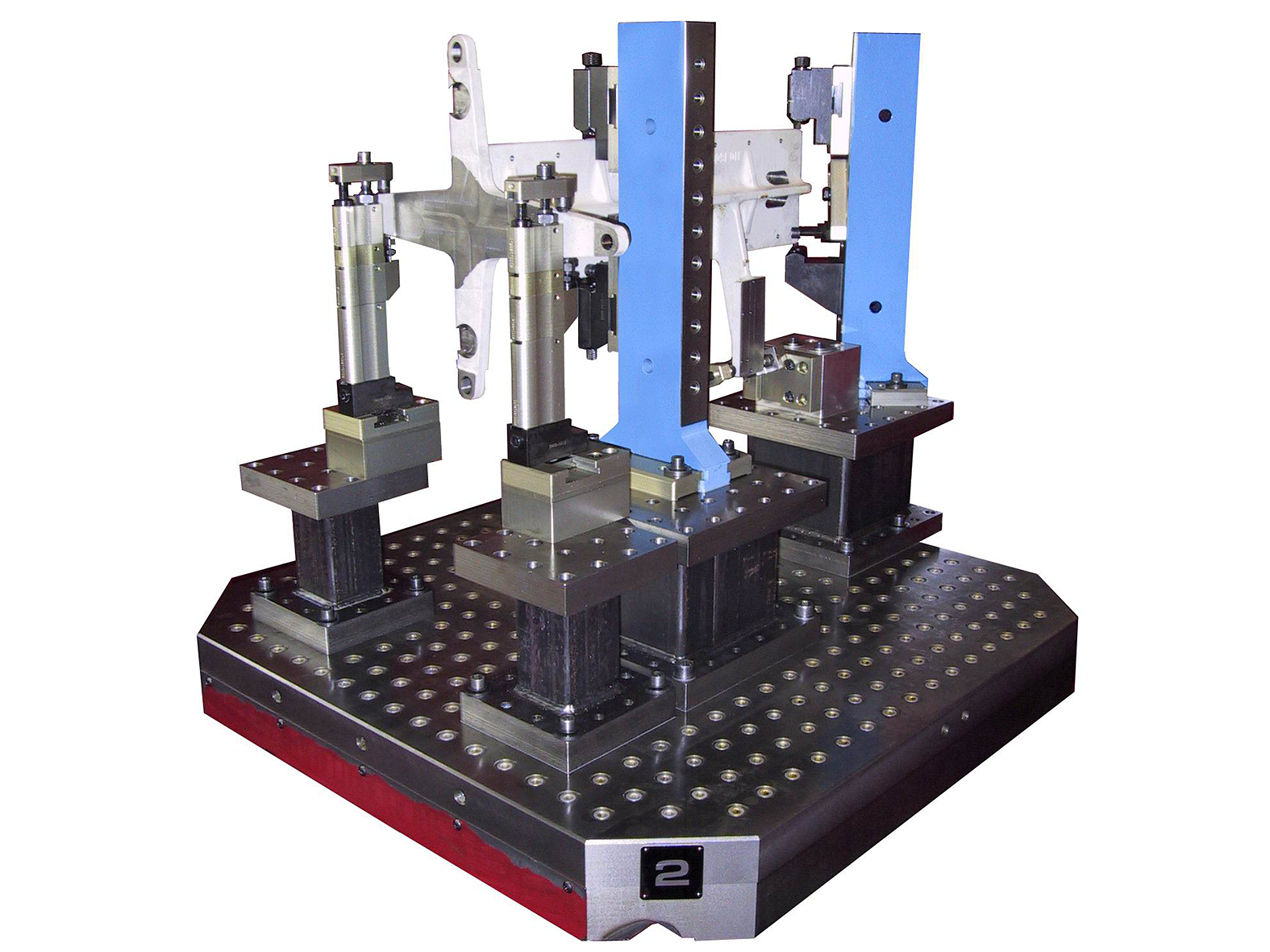

Customized solutions help to optimize machining potentials and to prepare your machine park for the higher demands of the market

Direct and low-cost integration in machine tables, pallets or fixtures is achieved with flanged base plates. DockLock zero-point clamping technology is designed for future-proof expansion, for example through the use of optional air-blast cleaning, contact and locking control, or external media passage.

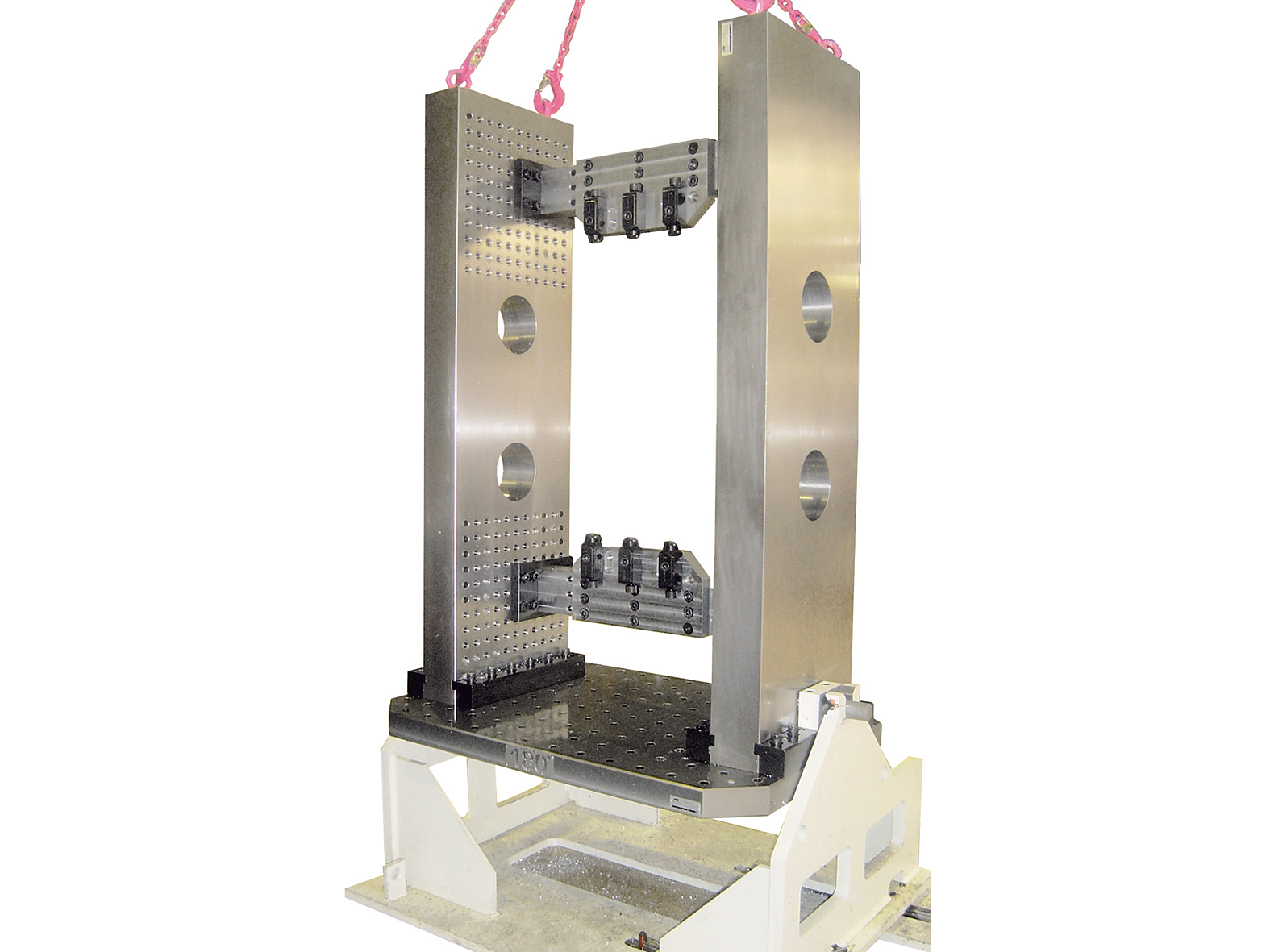

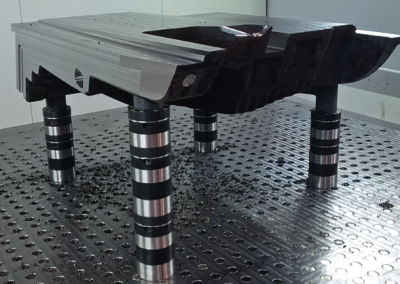

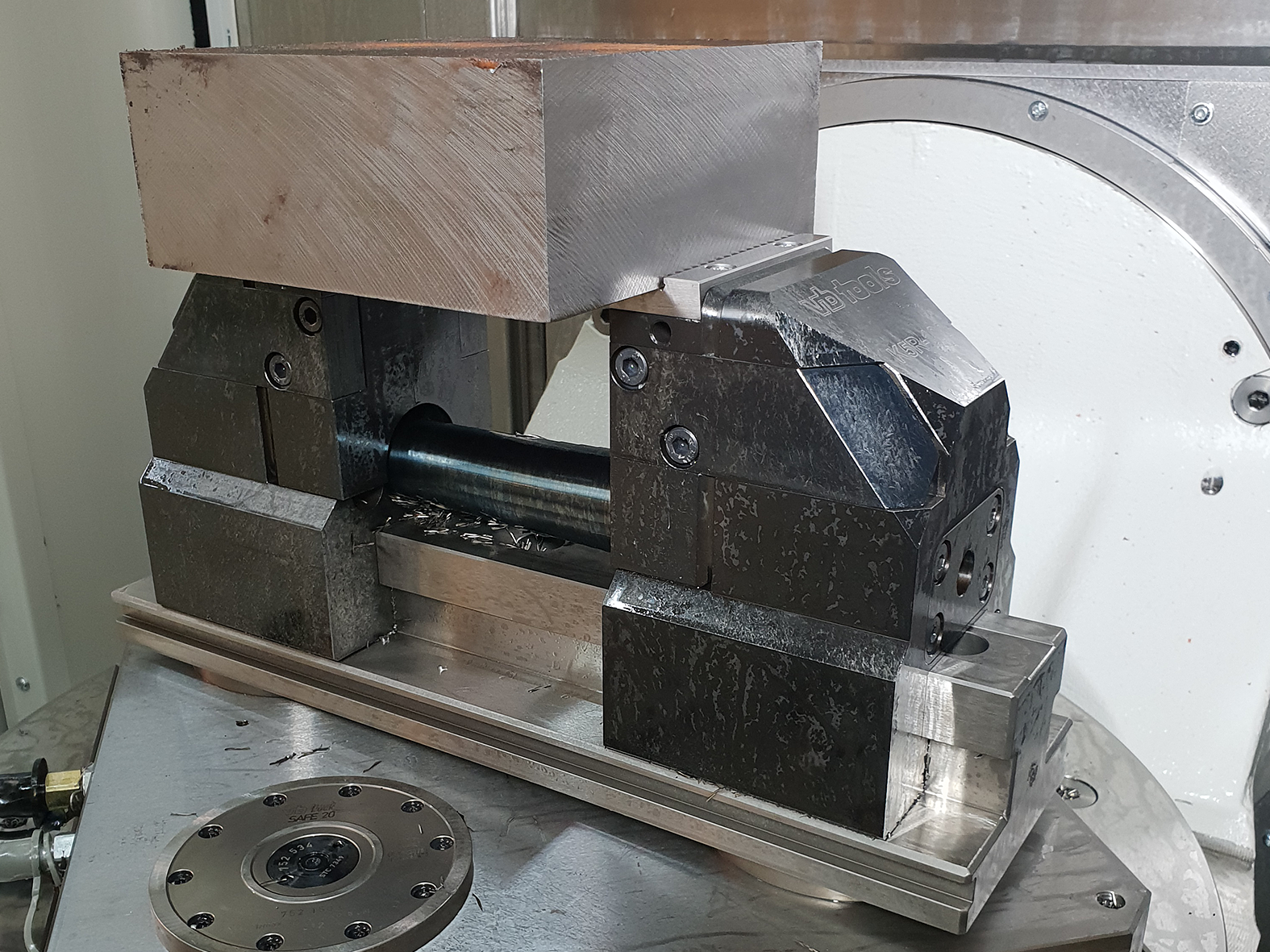

Complete machining in just one clamping setup

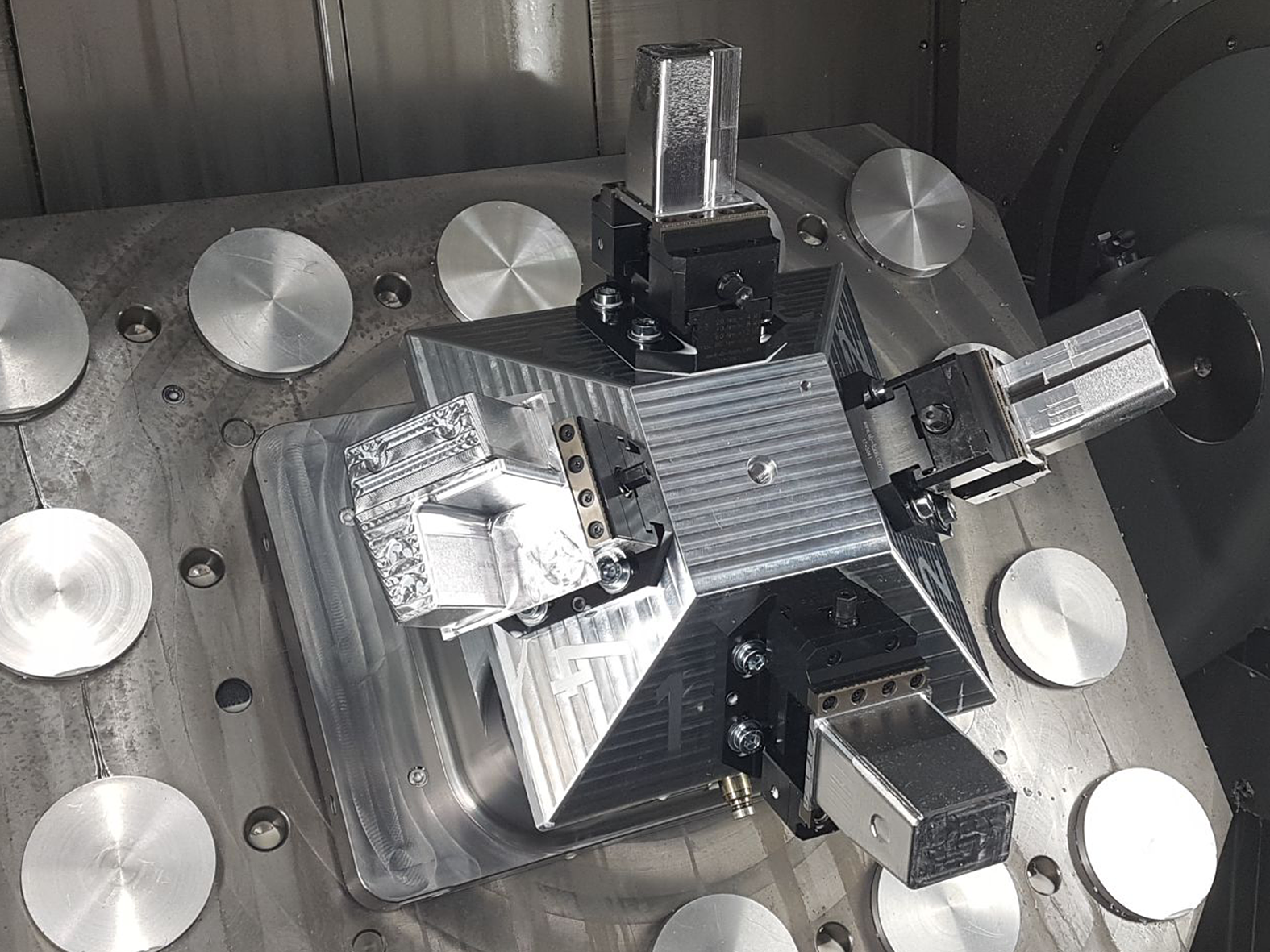

- For applications requiring a high level of flexibility

- For fixture building with requirements for high-end clamping devices

- Excellent for pilot production, before the final custom fixture is constructed

- Optimal supplement to the K5000/5001 line (clamping between columns): Complete machining in just one clamping setup

- Suitable for single parts, large series, multiple clamping setups, manual or hydraulic versions

Catalogue manual workholding technology

Here we go

Let us help you enter the age of automation

As part of the HAINBUCH Group, Vischer & Bolli Automation GmbH is a specialist and general contractor for the automation of entire manufacturing cells.